Industrial Applications:

High Temperature Maintenance

High Temperature Maintenance Ensuring

Thermal Stability in Industrial Processes.

High-temperature processes require reliable heat to protect material integrity and prevent failures. Drexan’s HeatTracer line, including PipeGuard Hot and Mineral Insulated cables, is designed for safe, high-performance operation, even in hazardous areas and during steam cleaning.

Why is High Temperature Maintenance Important?

Prevents Solidification & Thickening

Many fluids lose effectiveness when they cool below a critical temperature.

Maintains Product Quality & Consistency

Some materials must stay hot to preserve performance and reliability.

Reduces Energy Use & Heat Loss

Reheating cooled systems wastes energy and raises operating costs.

Prevents Condensation & Corrosion

Cool surfaces can attract moisture, causing rust or contamination.

Enhances Process & Worker Safety

Certain materials can become hazardous when reheated after cooling.

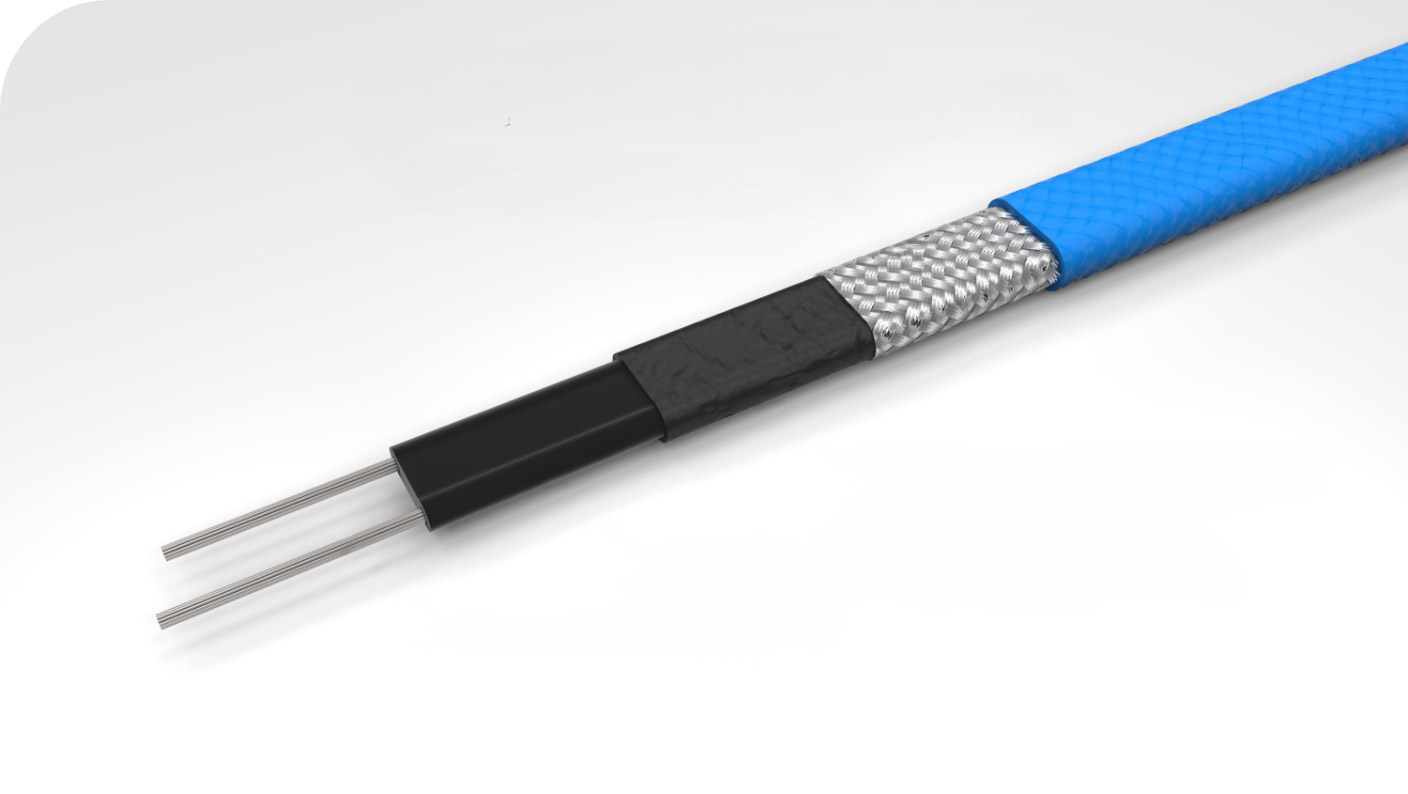

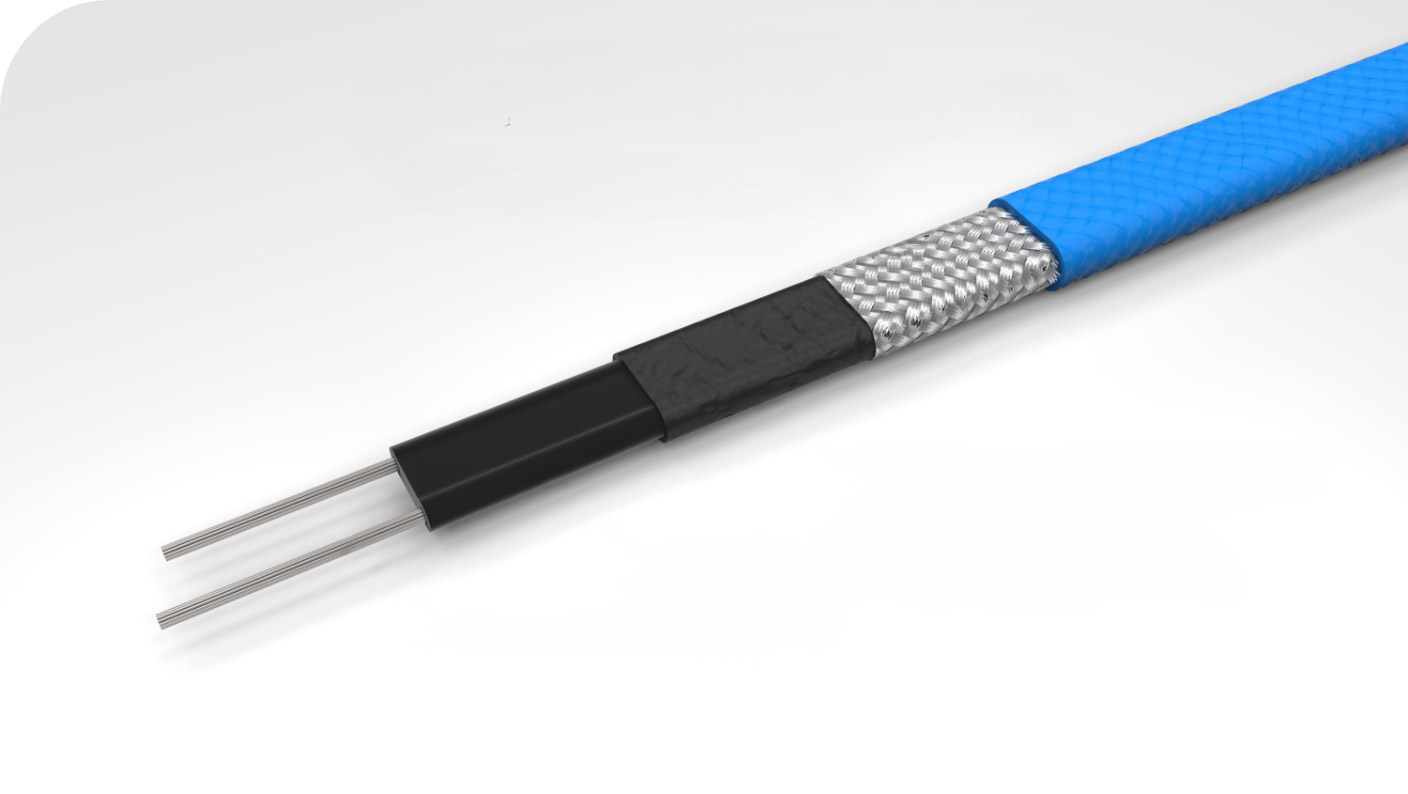

Drexan’s PipeGuard Self-Regulating Cables

Deliver precise, high-temperature protection with market-leading lifespan, and power accuracy.

Key Benefits:

- Built tough for both hazardous and non-hazardous environments

- Resists corrosion from harsh chemicals

- Globally certified: CSA (CUS) for North America.

- Installs easily on metal and non-metal pipes, tanks,

and vessels - Backed by the industry’s best warranty

Note: Hazardous locations are defined by the Canadian Electrical Code (CEC) Section 18 and the National Electrical Code (NEC) as areas with potential fire or explosion risks due to flammable gases, vapours, or dust.

Refer to the latest CEC and NEC codes for full compliance details.

Related Resources

Zone Information Guide for a complete list of hazardous locations

Download NEMA ratings for a complete list of enclosure types

Design Worksheet to choose the right trace heating system

Related Products

Trace Heating Cables

Need trace heating? We offer reliable, innovative solutions for freeze protection and temperature maintenance, with precise -0/+10% wattage tolerances.

Metallic Cable

Need trace heating? We offer reliable, innovative solutions for freeze protection and temperature maintenance, with precise -0/+10% wattage tolerances.

AMIGA

Our family of high-profile components for installation with Drexan’s Self-Regulating Heating Cables.

Mechanical Thermostats

Thermostats ideal for applications where freeze protection or lower-range temperature control is critical.

Where Reliability

Meets Innovation

At Drexan, we’re redefining trace heating with innovative, high-performance solutions that keep critical systems operational—no matter the conditions.